LMATS ISO 17025 Accreditation is recognised under ILAC MRA for Chemical Testing Laboratory

Chemical testing is one of the ancient test methods used to determine various aspects and behaviour of materials.

Some of the common applications of chemical testing in the engineering sector are chemical analysis of materials to:

- identify various elements

- alloy grade

- reaction of a certain chemical with a particular material

- dissolving material into chemical to evaluate its chemical properties.

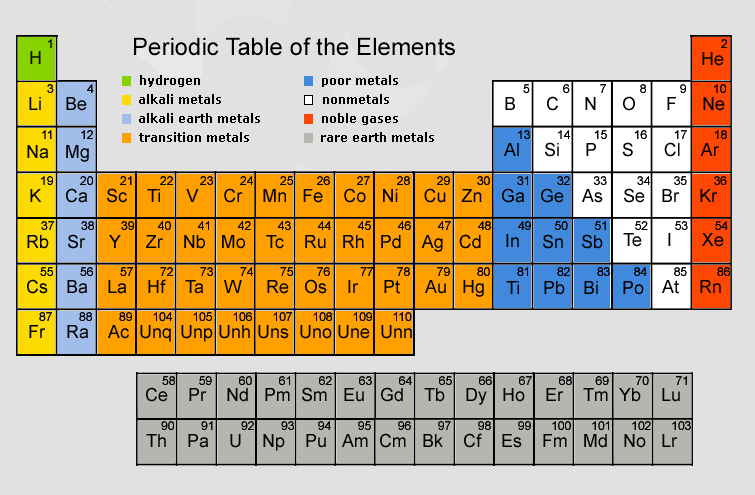

Chemical analysis is performed to determine the type and quantity of various elements such as:

- Fe - Iron

- C - Carbon

- Mn - Manganese

- S - Sulphu

- P - Phosphorus

- Si - Silicon

- Cr -Chromium

- Mo - Molybdenum

- Ni - Nicke

- Ti - Titanium

- V - Vanadium

- Nb - Niobium

- W - Tungsten

- Co - Cobalt

- Al - Aluminium

- Mg - Magnesium

- Zn - Zinc

- Cu - Copper

- Sn - Tin

- N - Nitrogen

- B - Boron

- O - Oxygen

- As - Arsenic

- Se - Selenium

- Pb - Lead

- Zr - Zirconium, etc.

LMATS can detect Boron content up to 0.001% in your steel to comply with Australian Standards.The chemical composition in a material decides the material grades and it applications.

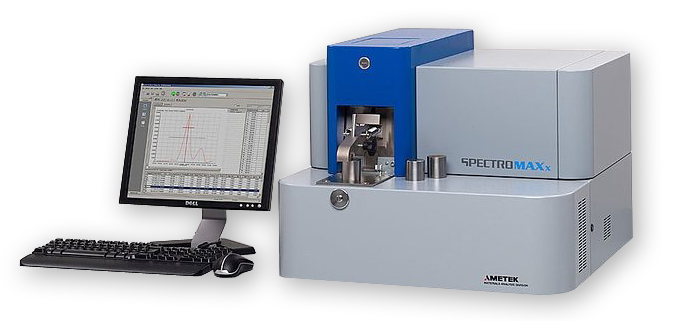

The fastest method to determine chemical composition is Optical Emission Spectrometry (O.E.S) followed by X-Ray fluorescence Spectrometry (XRF) and Inductive Coupled Plasma - Atomic Emission Spectrometry (ICP-AES). Laboratory based OES, XRF, ICP-AES are used for precision measurement of chemical composition and portable OES and XRF equipment are used for field material identification also called as Positive Material Identification ( PMI).

As a continual commitment to the industry LMATS has advanced its capability of chemical analysis (spectrometer analysis) of metallic samples by adding the latest technology spark atomic emission spectrometer (AES) for chemical analysis of metallic samples.

LMATS has invested in the latest technology spectrometer for chemical analysis of metallic samples, replacing our older optical emission spectrometer (OES).

The combination of LMATS ability to perform chemical analysis along with several engineering tests and test result interpretation by experienced metallurgists ensures that the clients receive report, within the shortest period of time, on accurate identification of material grade for replacement of critical parts and or reverse engineering.

Typical applications:

- Production quality control in foundries and steel mills

- Global recognition facilitating acceptance of test and inspection compliance and certification data, accompanying goods across international borders

- Product certification by analyzing chemical composition of a product sample

- Calculate carbon equivalent for welding purpose by analyzing chemical composition

- Analyze chemical composition to identify material type for the purpose of part replacement, failure investigation, reverse engineering, etc

The elements commonly analysed are:-

LMATS also offers in-situ portable O.E.S. Spectroscopy and PMI-XRF-Spectroscopy technologies