Technology

Eddy-current test uses electromagnetic induction to detect flaws in conductive materials. The eddy current test set-up consists of a circular coil which is placed on the test surface.  The alternating current in the coil generates changing magnetic field which interacts with the conductive test surface and generates eddy current. The flow of eddy current can be disrupted due to change in resistivity or conductivity, magnetic permeability, any physical discontinuities. The change in eddy current flow and a corresponding change in the phase and amplitude is measured against known values.

The alternating current in the coil generates changing magnetic field which interacts with the conductive test surface and generates eddy current. The flow of eddy current can be disrupted due to change in resistivity or conductivity, magnetic permeability, any physical discontinuities. The change in eddy current flow and a corresponding change in the phase and amplitude is measured against known values.

Eddy current test method can detect very small cracks in or near the surface of the material, the surfaces need minimum preparation. The biggest advantage of the eddy current test method is that is can be employed to determine surface flaws on painted or coated surface. Eddy current flaw detection is commonly used in the aerospace industry, crane industry, concrete pumping industry and other general industries where the protective surface coating cannot be removed.

Testing

LMATS performs test in accordance with AS 4544, ISO 17643, ASME V Article 8, AS 2331.1.4, ASTM E376, ASTM E1004, ASTM E703, ASTM E566 and similar national and international standards.

Compared to other surface flaw detection methods, eddy current testing requires highly trained, skilled and experienced technicians.

Eddy current crack & flaw detection (on painted surfaces)

Eddy current crack and surface flaw detection testing can be done on various coated / painted engineering components such as in-service painted structures, walls, beams, pipes, coloumns, welds, forgings and wrought products, heat exchanger tubes and similar products. LMATS test procedures are based on national and international standards such as AS 4544, ISO 17643, ASME V Article 8.

Eddy current crack detection is performed on coated steel components and non-coated aluminium and copper alloys.

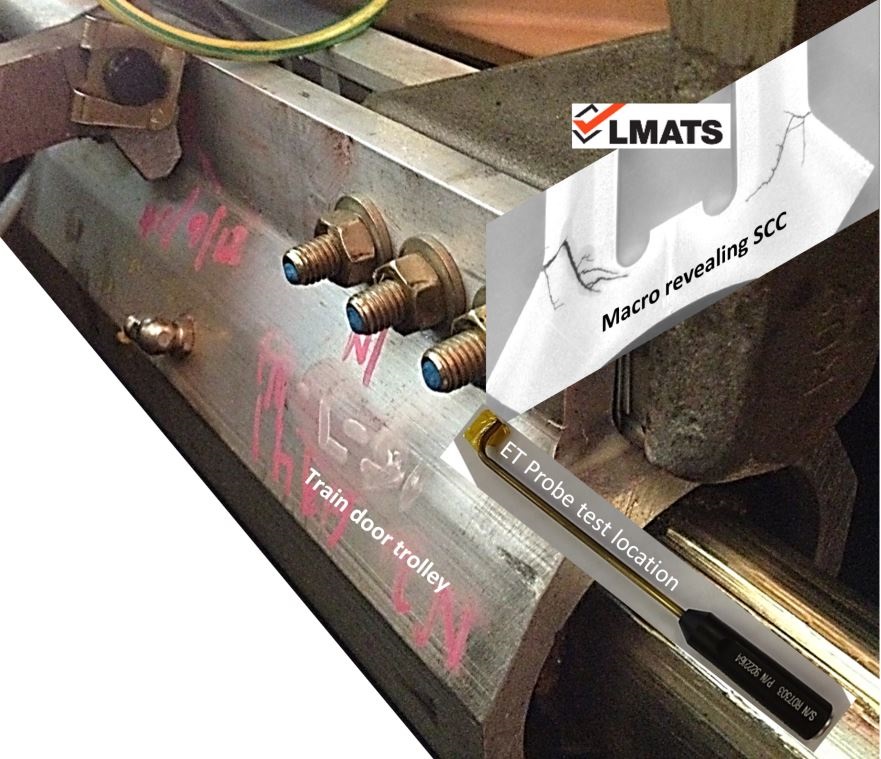

The photo below shows LMATS staff detecting SCC - Stress Corrosion Crack in a train door trolley using a right angle probe. Access to this trolley is very limited and only the probe can be inserted between the train door and the trolley.

Crane Inspections

The crane industry and crane owners benefits most from the application of eddy current test method to detect surface flaws underneath the protective coating (paint ). The exorbitant cost of paint removal and repainting is eliminated by applying eddy current flaw detection method as compared to magnetic particle test. It is also useful for making electrical conductivity and coating thickness measurements. Eddy current test is commonly employed for rapid thickness testing of coatings - conductive and non-conductive.

See also LMATS crane inspection services.

Coating Thickness Testing

Electromagnetic testing is performed on engineering components to determine thickness of metallic and non-metallic coatings, weld overlay and residual bond, corroded samples wall thickness and similar applications.

LMATS performs testing to standards AS 2331.1.4, ASTM E376 and similar international standards.

Conductivity test

LMATS performs electromagnetic testing to determine resistivity and conductivity.

The resistivity or conductivity in a product is dependent on the type of material grade, alloy, shape, design, microstructure, heat treatment condition, graphite or carbides or porosity in the material, strength and hardness.

This test is successfully used for sorting of material according to material physical, chemical and mechanical properties. Material sorting is performed in accordance with ASTM E566.

Advanced Methods

LMATS has a range of advanced eddy current methods including eddy current array (ECA) and pulsed eddy current testing (PEC). These have advantages over conventional ET.

Find out more

The principle of eddy current test which measures the change in resistivity in the conductive material makes it useful in wide range of applications such as conductivity measurement, sorting of material, assessment of heat treatment condition, sorting of materials on the basis of hardness and strength, thickness measurement of thin components.