TOFD (Time Of Flight Defraction) is one of the Ultrasonic Testing methods most widely used in tank floor testing and for vertical discontinuities such as crack sizing. TOFD can be used on its own or in conjunction with PAUT Phased Array Ultrasonic testing to provide 100% coverage, highest probability of detection, accuracy of measurement and precise sizing of a discontinutiy.

Accurate TOFD measurement of crack dimensions helps to keep expensive components and equipment in service as long as possible with minimal risk of failure.

LMATS Capabilities

- Advanced Weld Inspection Solutions

- Advanced Corrosion Inspection and detection

- Advanced Stress Corrosion Inspection and detection

- Advanced Tube Inspection

- Advanced Composite Inspection

- Weld root erosion testing in fluid carrying pipelines, high pressure steam pipes in power stations and refrigeration plants

- Fatigue crack sizing & monitoring to continue plant operation safely before reaching critical crack size

- Stress corrosion cracks & Creep cracks mapping & monitoring

Advantages of TOFD over Conventional UT

- Precise sizing capability makes it an ideal flaw monitoring method

- Highly sensitive to all weld flaw types

- Based on diffraction, so relatively indifferent to weld bevel angles and flaw orientation

- Uses time of arrival of signals received from crack tips for accurate defect positioning and sizing

- Quick to set up and perform an inspection, as a single beam offers a large area of coverage

- Rapid scanning with imaging and full data recording

- Can also be used for detecting irregularly shaped areas of metal lossduring corrosion inspections

- Required equipment is more economical than phased array, due to conventional nature (single pulser and receiver) and use of conventional probes

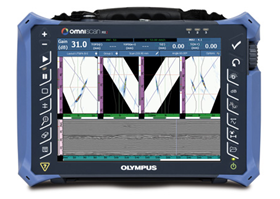

Olympus OmniScan MX2 pictured above.

Technique Explanation

Whilst conventional ultrasonics uses shear/transverse waves as the primary mode of detection, TOFD uses longitudinal waves as the primary detection mode. Ultrasonic sensors are placed on each side of the weld. One sensor transmits the ultrasonic beam into the material and the other sensor receives both reflected and diffracted ultrasound from anomalies and geometric reflectors.

Using ultrasonic beam spread, TOFD provides a wide area of coverage for anomaly detection in the material being tested. When the beam impinges on a flaw tip, it is diffracted in all directions. Measurement of the time of flight of this diffracted beam enables accurate and reliable flaw detection and sizing. This is the case even if the crack is not oriented to the intial beam direction. During typical TOFD inspections, A-scans are collected and used to create B-scan (side view) images of the weld. Post acquisition analysis is done using software to measure the flaw length and through-wall height.

Contact LMATS for more information on +61 3 9399 8145 or via the form.