Inductively Coupled Plasma Atomic Emission Spectrometer (ICP-AES)

Overview of ICP Technique

ICP is versatile composition analysis technique for various applications in metallurgical, geological, environment and water, agricultural and food, organic, pharmaceutical and allied industries. It is great for materials that cannot be readily analysed using other spectroscopy techniques. e.g. Spark OES and XRF Spectrometer. This includes metal filings or shavings, as well as dissolved or suspended solids in liquids, particulates, granular, agglomerates, soil, compounds, ores, trace elements in liquid, wine, milk, food, etc.

NATA Accreditation

LMATS is NATA accredited for ICP on metal alloys. Find out more on our accreditation page.

Applications and Benefits

LMATS applies ICP analysis on:

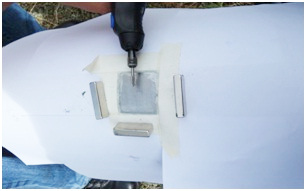

- Drillings/burrs from live pipelines for material confirmation and carbon equivalent for welding purposes

- Live pipelines, in-situ machinery and plant, and in-service structures - enabling us to perform grade analysis with non-invasive methods

- Tiny metallic objects in confectionary, metallic filings in engine oil, or tiny residues from failed parts to assist with failure investigations

- Samples that cannot be tested with OES, such as manganese steels, nickel alloys, magnesium alloys, zinc alloys, titanium alloys and other rare and exotic alloys

- Heavy metals like cadmium, arsenic, lead and other potentially toxic metals and contaminants

- Geological and environmental specimens including soils, sediments, sludges, minerals, water and other organic matter

ICP can be applied in the following applications

- Metallic alloys – High purity metals, Steel, Al, SS, brass, precious metals, solders, tin

- Geological - Coal, minerals, fossils, ore, rocks, sediments

- Industrial – Glass, ceramics, paint and coatings, polymers, packaging materials, fibres

- Petroleum – Oils, petroleum products, lubricants, fossil fuel etc

- Environmental– Soil, water, Brines, coal fly ash, dust, plating bath, sewage sludge, slag, seawater

- Agricultural – Food, fertilizers, roots, Animal tissues, beverages, feeds, nutrients, pesticides, plant materials, rice flour, soils, milks, vegetables, wheat flour, milk powder

- Organic - Adhesives, amino acids, antifreeze, combustion materials, cosmetics, cotton cellulose, dried wood, dyes, elastomers, epoxy, organometallic, organophosphates, organic solvent, sugars

- Other – Ash, acids, carbon, catalytic materials, electronics, film, phosphates, semiconductors, superconducting materials

How LMATS ICP works

LMATS uses the latest technology Agilent 5900 SVDV ICP-OES. Samples are introduced into the plasma in a process that ionizes and excites atoms, emitting electromagnetic radiation at characteristic wavelengths of each element. The wavelength intensity can be measured at concentrations as low as ppm and ppb levels. LMATS ' ICP is equipped with the Agilent IntelliQuant screening function that quickly screens samples and determines the approximate concentration of up to 70 elements from the periodic table. Considering the simultaneous analysis method and the attached auto sampler, LMATS can efficiently manage several samples a day ensuring quality results.

The ICP technique needs only few grams of sample to run multiple tests simultaneously. After the test tubes containing digested specimen are placed correctly in the auto sampler, the ICP can rapidly run an automatic program and identify desired elements and measure concentration level accurately for each element in each specimen instantly. Preparation of specimen includes dissolving a portion of material, contaminants, small specimens, and residues including drillings/burrs collected from live pipelines.

Alternatives

LMATS can also perform onsite spark spectrometry on in-situ parts using LMATS portable O.E.S. that can also measure carbon content. For most in-situ solid metallic objects, LMATS portable XRF Spectrometer can be used to identify material and general chemical composition.